Introduction

One of the main components within the SAP system is materials.

The materials are used in practically all SAP modules (MM, SD, FI, CO, PP, QM, etc.) and tend to be a reason for great discussions within the projects, mainly due to the innumerable number of possibilities they provide to the business.

The registration of material within SAP is immense, with each field filled in, a system function can be activated, a process can be modified, the accounting for that material can change, etc.

In today’s post, we will talk about the types of materials within the SAP system, why there is this type of “classification” in the system, in addition to some tips.

What is a Material Type?

The type of material is nothing more than a categorization of the materials contained within the SAP system.

This categorization helps us to differentiate one material from the other in several aspects:

- Whether the numbering of that material will be done automatically by the system or if it can be defined by the person who will create a material.

- What is the numbering range that material should belong to (For example Raw materials can be configured to always be within the range 199999 to 299999, so it will be easier for the business to distinguish a material just by material number).

- What sequence of screens that particular type of material should have (when we talk about screens, we are also talking about which fields will be available for a certain type of material).

- Among several others.

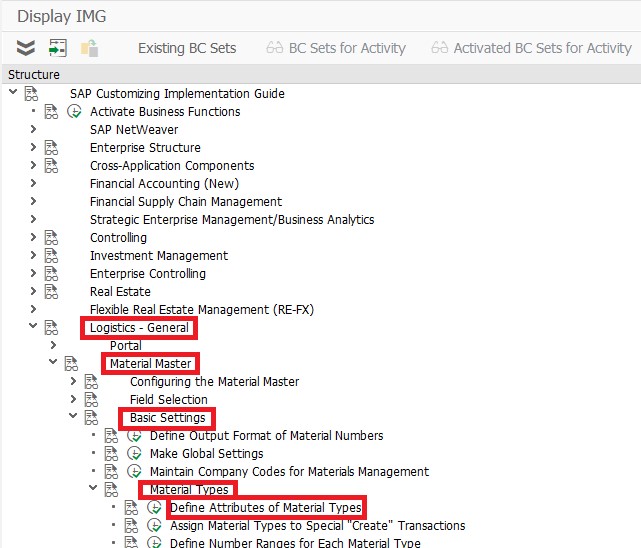

For example, we can check the types of materials using the path below:

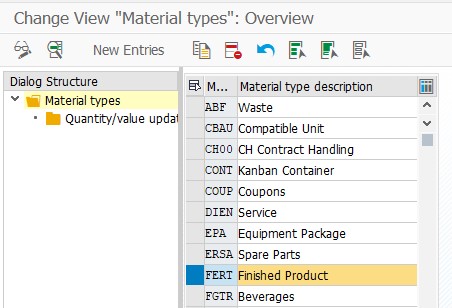

The list of all material types present in the system is displayed:

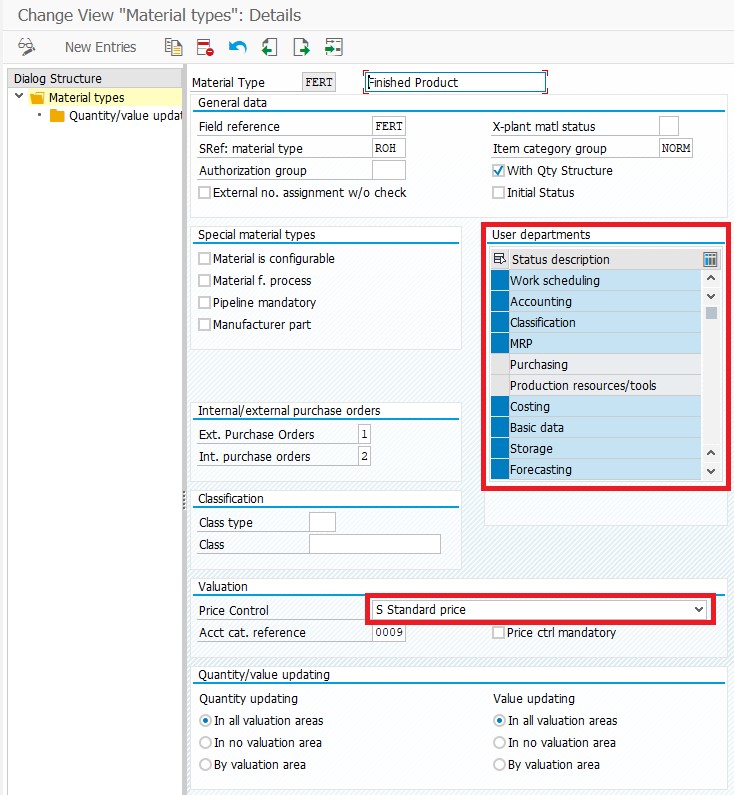

When selecting the type of material FERT (Finished Product) and clicking on the Detail button, we can view its configuration:

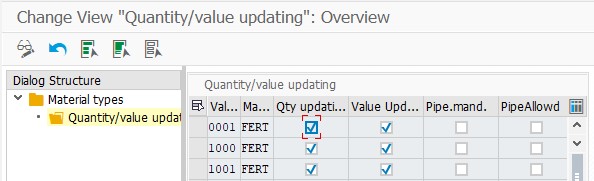

In addition, as mentioned above, we can verify whether that particular type of material for a given plant should be controlled by the system only by quantity or if it should also be controlled by value.

*A Valuation Area equals to Plant.

As we can see, numerous configurations can be made by Material Type.

SAP recommends that you never change the default settings for the types of materials that are already preconfigured by SAP itself.

When there is a specific need in any project, the best practice is to create a new type of material (with a copy of the most similar type of material).

The name of the new material type must begin with the letter Z or Y (industry standard).

Standard SAP Material Types

As mentioned above, SAP standardizes many material options.

Currently, in the SAP system, I am using, we have 39 types of materials available:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

I have worked for clients where it was decided that no standard material would be used and Z material types were created for all necessary material types, just for the sake of keeping the types provided by SAP untouchable.

In other customers, the types of materials supplied by SAP were used and no type of material Z was created.

It depends on the chosen approach.

Main related SAP transactions

Below are the main transactions related to the types of materials:

- OMS2: Display/Create/Change/Delete material types.

- OMS2: Configure the material accounting by the quantity and/or value per plant.

- MMNR: Define and assign number range to material types.

Conclusion

The subject “Material” is always extremely important for each and every SAP project.

When this subject is not discussed extensively, the chances of problems occurring in the future are very great.

The “Type of Material” is extremely important in this context and that’s exactly why I decided to create this post.

If you liked this post, be sure to subscribe to our newsletter to receive first hand the next posts and share this post with your friends.

If you have any suggestions (including subjects you would like to read about), feel free to send an email to sapsteps@sapsteps.com.

A big hug,

Bruno César